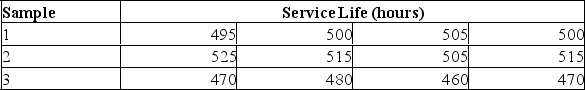

A design engineer wants to construct a sample mean chart for controlling the service life of one of the types of light bulbs his company produces.He knows from numerous previous samples that this service life is normally distributed with a mean of 500 hours and a standard deviation of 20 hours.On three recent production batches,he tested service life on random samples of four bulbs,with these results:  If he uses upper and lower control limits of 520 and 480 hours,what is his risk (alpha) of concluding service life is out of control when it is actually under control (Type I error) ?

If he uses upper and lower control limits of 520 and 480 hours,what is his risk (alpha) of concluding service life is out of control when it is actually under control (Type I error) ?

Definitions:

Q3: The time interval between ordering and receiving

Q6: In an A-B-C inventory system,the typical percentage

Q28: If,in a single period inventory situation,the probabilities

Q46: A lot can be "accepted" or "rejected"

Q54: Which of the following is not related

Q56: Which of the following is not one

Q57: Studies on a bottle-filling machine indicates it

Q75: A fishbone diagram would be used to:<br>A)categorize

Q106: A Methods and Measurements Analyst for Digital

Q130: A town's department of public works is