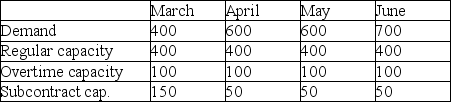

Byron's Manufacturing makes tables. Demand for the next four months and capacities of the plant are shown in the table below. Unit cost on regular time is $40. Overtime cost is 150% of regular time cost. Subcontracting is available in substantial quantity at $75 per unit. Holding costs are $5 per table per month; back orders cost the firm $10 per unit per month. Byron's management believes that the transportation algorithm can be used to optimize this scheduling problem. The firm has 50 units of beginning inventory and anticipates no ending inventory.

a. How many units will be produced on regular time in June?

a. How many units will be produced on regular time in June?

b. How many units will be produced by subcontracting over the four-month period?

c. What will be the inventory at the end of April?

d. What will be total production from all sources in April?

e. What will be the total cost of the optimum solution?

f. Does the firm utilize the expensive options of subcontracting and back ordering? When; why?

Definitions:

External Forces

Factors or influences originating outside an entity that can cause changes or impacts within it.

Interdisciplinary Meeting

A gathering of professionals from various disciplines to collaborate, share insights, and create comprehensive plans for patient care or projects.

Deep Breath

A large inhalation of air into the lungs, used in various health and relaxation practices to increase oxygen intake.

Emergency Preparedness

The process of planning and taking measures ahead of time to ensure effective response to disasters, emergencies, or significant unexpected events.

Q26: Identify the types of planning files used

Q41: Which of the following is not a

Q42: What is the primary management challenge when

Q54: Identify the disadvantages of the Gantt load

Q66: The number-one reason driving outsourcing for many

Q66: An item's holding cost is 60 cents

Q68: Identify some business processes that are outsourced.

Q69: If a manager conducting a time study

Q82: Describe ABC inventory analysis in one sentence.

Q112: A manager is applying the transportation model