In the production of vitamin capsules,the proportion of calcium in each capsule has a specification of 48 ± 18 parts per million (ppm).An initial random sample of 100 capsules revealed a sample average calcium content of 44.5 ppm and a sample standard deviation of 3.2 ppm.Management uses  - and R-charts to monitor the calcium amount using samples each of size 4.

- and R-charts to monitor the calcium amount using samples each of size 4.

The charts depict an in-control process.The center line of the R-chart is 6.7 and the center line of the  -chart is 44.8.

-chart is 44.8.

a sample standard deviation of . Management uses - and -charts to monitor the calcium amount using samples each of size 4 .

The charts depict an in-control process. The center line of the -chart is and the center line of the -chart is .

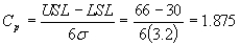

a. Compute for this process using estimates of the process mean and standard deviation derived from the random sample.

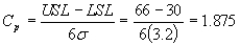

b. Compute for this process using estimates of the process mean and standard deviation derived from the control chart parameters.

c. Compute for this process using estimates of the process mean and standard deviation derived from the random sample.

c. Compute for this process using estimates of the process mean and standard deviation derived from the control chart parameters.

d. What do the differences between the values of and tell you?

Definitions:

Q11: <br>What is knowledge sharing at ConocoPhillips based

Q23: After using an ATM machine,Deborah forgets to

Q23: With respect to the six competencies summarized

Q39: Describe the organizational structure of the magnesium

Q46: Which of the following personal leadership competencies

Q48: In the context of the dimensions of

Q52: Internal customers of an organization are those

Q63: Which of the following is a creativity

Q72: An effective knowledge management system should include

Q79: What were some of the errors that