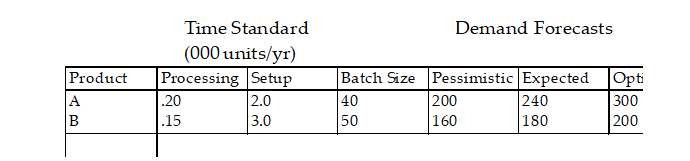

Table 5.2

High Tech, Inc. is producing two types of products: A and B. Both are produced at the same sawing operation. Because of demand uncertainties, the operations manager obtained three demand forecasts (pessimistic, expected, and optimistic) . The demand forecasts, batch sizes (units/batch) , processing times (hr/unit) , and setup times (hr/batch) follow.

The sawing machines operate on two 8-hour shifts, 5 days per week, and 50 weeks per year. The manager wants to maintain a 10 percent capacity cushion.

-Using the information from Table 5.2, what is the maximum number of machines needed (assuming no reliance on short- term option) ?

Definitions:

Q7: The five categories of activities (operation, transportation,

Q7: A route planning seeks to find the

Q29: Supply chain managers are not catalysts to

Q34: The new service/product development process begins with

Q40: As the setup cost (S) increases, the

Q41: A milling operation has historically produced

Q105: Which statement on reengineering and process improvement

Q126: Product traceability follows the path of defective

Q127: Reducing the lead times associated with purchasing

Q174: Purely random, unidentifiable sources of variation that