SCENARIO 19-4

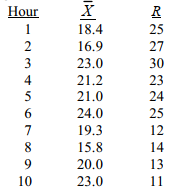

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits.The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours.The sample mean and range for each hour are listed below. She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds,respectively.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds,respectively.

-Referring to Scenario 19-4,suppose the supervisor constructs an x̄ chart to see if the process is in-control.What are the lower and upper control limits of this chart?

Definitions:

Q14: If a new machine of a production

Q15: Referring to Scenario 19-6,a p control chart

Q31: Referring to Scenario 16-14,the best interpretation of

Q40: To construct a bootstrap confidence interval

Q46: If we are performing a two-tail test

Q49: Referring to Scenario 20-2,what is the optimal

Q54: Vertical analysis expresses each item in a

Q61: Referring to Scenario 18-12,the null hypothesis that

Q102: Referring to Scenario 18-1,suppose the builder wants

Q125: Which of the following situations suggests a