Additional Application

THE AVERAGE COST OF PRODUCING AIRPLANES

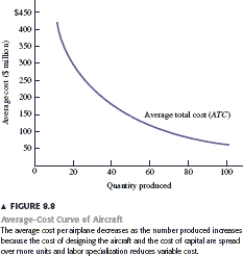

Suppose you want to design and manufacture a new airplane, one with a performance level comparable to the Boeing 737. To get a rough idea of how much it would cost to design the new aircraft and then produce a particular quantity of airplanes, you could use the Airframe Cost Model developed by U.S. National Aeronautics and Space Administration NASA) . Figure 8.8 shows the average cost of production for up to 100 airplanes. The fixed cost includes the cost of designing the aircraft and the cost of capital used in the production process, including the machine tools used to fabricate the components of the aircraft. Together these fixed costs add up to about $2.45 billion. The variable cost includes the costs of the materials and labor used to produce the components and then assemble the aircraft. The NASA cost model suggests that the average variable cost decreases as the number of airplanes increases because of labor specialization. The average- cost curve in Figure 8.8 is negatively sloped because as the quantity of aircraft increases, the fixed cost is spread over more units and labor specialization pulls down the average variable cost. The average cost decreases from $435 million for a quantity of 10 aircraft, to $257 for 20 aircraft, and so on down to $86 million for 100 aircraft.

The average-cost curve is negatively sloped, implying that there are no diminishing returns in the production of airplanes. This occurs because the cost model assumes that as output increases, production occurs over a longer period of time. Diminishing returns normally occur if an increase in output requires an increase in the number of workers in a given production facility. In the normal case, each worker becomes less productive because each worker gets a smaller share of the production facility-plant and equipment such as machine tools. But if doubling output means that we operate a given production facility twice as long, diminishing returns wonʹt occur: Each worker still gets the same share of the facility, but simply uses the facility for twice as much time.

The average-cost curve is negatively sloped, implying that there are no diminishing returns in the production of airplanes. This occurs because the cost model assumes that as output increases, production occurs over a longer period of time. Diminishing returns normally occur if an increase in output requires an increase in the number of workers in a given production facility. In the normal case, each worker becomes less productive because each worker gets a smaller share of the production facility-plant and equipment such as machine tools. But if doubling output means that we operate a given production facility twice as long, diminishing returns wonʹt occur: Each worker still gets the same share of the facility, but simply uses the facility for twice as much time.

-Recall the Application on ʺThe Average Cost of Producing Airplanes.ʺ The costs of designing the aircraft and the machine tools used to fabricate the components for the aircraft are:

Definitions:

Piston

A cylindrical component that moves up and down in an engine's cylinder, converting combustion energy into mechanical motion.

Compress

To apply pressure to something or reduce its volume by squeezing it tightly, often referring to gases, fluids, or solids in various contexts.

Cylinder

A fundamental component of engines where fuel combustion occurs, generating power; it’s typically cylindrical in shape.

Pressure Differential Valve

A valve in a dual-circuit hydraulic brake system that closes off one circuit in response to a leak in order to maintain hydraulic pressure in the other circuit. Preserves brake pressure at two of the four wheels.

Q29: A perfectly competitive firm can:<br>A)affect the market

Q80: If we are on the upper portion

Q131: Entry leads reduces firm profits because it

Q159: Other things being equal, if the average

Q161: How do monopoly prices and quantities produced

Q167: Suppose that a price discriminating monopolist is

Q173: Table 7.2 contains price, demand, and cost

Q178: Recall the Application. When a patent ends

Q201: Figure 5.2 presents a firmʹs marginal, average

Q285: Suppose that a monopolistically competitive market is