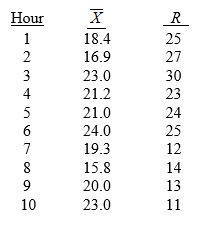

TABLE 17-4

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits. The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours. The sample mean and range for each hour are listed below.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds, respectively.

-Referring to Table 17-4, suppose the supervisor constructs an R chart to see if the variability in collection times is in-control. This R chart is characterized by which of the following?

Definitions:

Practical Capacity Percentage

The ratio of actual production volume to the maximum possible volume that could be achieved under optimal conditions.

Time-based Activity-based Costing

A refinement of Activity-based Costing that assigns costs based on the actual time spent on activities, providing a more accurate allocation of overheads.

Closest Competitor

The company or brand that most directly competes with another in terms of product offerings, market share, or business model.

Capacity Analysis

Capacity analysis is the process of evaluating the production capacity of a business to understand its ability to meet future demands. It involves assessing both physical and human resources.

Q14: Referring to 14-16, the 0 to 60

Q14: Developing operational definitions for each critical-to-quality characteristic

Q65: Referring to Table 6-1 and assuming that

Q69: If the number of blocks in the

Q70: One of the consequences of collinearity in

Q73: The control limits are based on the

Q143: Which of the following methods should not

Q248: Referring to Table 19-5, what is the

Q315: A medical doctor is involved in a

Q322: Referring to Table 14-12, predict the meter