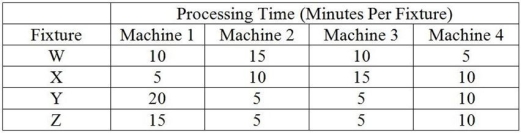

Table 5.3

King Supply makes four different types of plumbing fixtures: W, X, Y and Z. The contribution margins for these products are: $70 for Product W, $60 for Product X, $90 for Product Y and $100 for Product Z. Fixed overhead is estimated at $5,500 per week. The manufacture of each fixture requires four machines, Machines #1, 2, 3 and 4. Each of the machines is available for 40 hours a week and there is no setup time required when shifting from the production of one product to any other. The processing requirements to make one unit of each product are shown in the table. Weekly product demand for the next planning period has been forecasted as follows: 70 Ws, 60 Xs, 50 Ys and 30 Zs.

In the questions that follow, the traditional method refers to maximizing the contribution margin per unit for each product, and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

-Use the information in Table 5.3. Using the bottleneck method, which product should be scheduled first?

Definitions:

Stramenopiles

A diverse group of eukaryotic organisms, including diatoms, brown algae, and water molds, characterized by the presence of fine, hairlike projections on their flagella.

Paramecium

A genus of unicellular ciliates, commonly studied as a representative of the ciliate group, known for their ability to move using tiny hair-like structures called cilia.

Alveolates

A group of protozoans, including dinoflagellates, apicomplexans, and ciliates, characterized by the presence of alveoli structures beneath their cell membranes.

Cellular Slime Mold

Amoeba-like protist that feeds as a single predatory cell; joins with others to form a multicellular spore-bearing structure under unfavorable conditions.

Q11: A company is interested in monitoring

Q14: Use the information in Table 5.2. Using

Q52: The manufacturer developed and tested a questionnaire,

Q69: The production of 240 units during a

Q88: Line balancing strives to create workstations so

Q102: What are some of the approaches used

Q104: Regarding the Eight Types of Waste that

Q125: ISO 9001:2008 standards provide strict guidelines for

Q159: Quality at the source is a philosophy

Q176: A metal-cutting operation has a target value