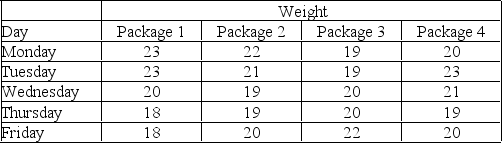

A quality analyst wants to construct a sample mean chart for controlling a packaging process. He knows from past experience that when the process is operating as intended, packaging weight is normally distributed with a mean of twenty ounces, and a process standard deviation of two ounces. Each day last week, he randomly selected four packages and weighed each. The data from that activity appear below.

(a) If he sets an upper control limit of 21 and a lower control limit of 19 around the target value of twenty ounces, the control chart is based on what value of z?

(a) If he sets an upper control limit of 21 and a lower control limit of 19 around the target value of twenty ounces, the control chart is based on what value of z?

(b) With the UCL and LCL of part a, what do you conclude about this process-is it in control?

Definitions:

Hunting and gathering

A mode of subsistence involving the procurement of wild plants and animals for food.

Pastoralism

a form of agriculture where animals are raised for food, fiber, and other products, often involving nomadic or semi-nomadic herding.

Legitimate use of force

Refers to the socially sanctioned, legal, or accepted use of physical power or coercion by individuals or institutions, especially by the state or law enforcement, to maintain order or enforce laws.

Rational-legal authority

A form of leadership where authority is based on legal legitimacy and bureaucratic procedures, as opposed to traditional or charismatic forms of governance.

Q46: Which of the following is NOT a

Q55: The Central Limit Theorem states that when

Q59: Which of the following statements regarding FedEx

Q106: Inputs to a production system that are

Q139: A grocery chain is deciding on where

Q170: Explain how a Pareto chart can identify

Q187: Construct a cause-and-effect chart for a missed

Q195: Jars of pickles are sampled and weighed.

Q223: An organization's approach to transforming resources into

Q251: Identify the formulas for the following terms