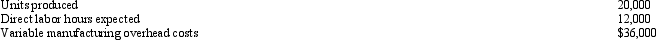

Exhibit 19-7 The following figures represent 100% capacity for Starr Manufacturing: Starr Manufacturing normally produces at 100% capacity. During the month of October, the company started and completed 10,000 units of product, using variable manufacturing overhead costs of $20,000. The company used 6,400 direct labor hours in October instead of the 6,000 hours expected for the activity level achieved.

Starr Manufacturing normally produces at 100% capacity. During the month of October, the company started and completed 10,000 units of product, using variable manufacturing overhead costs of $20,000. The company used 6,400 direct labor hours in October instead of the 6,000 hours expected for the activity level achieved.

-Refer to Exhibit 19-7. Based on the information above, the manufacturing overhead efficiency variance is:

Definitions:

Normal Standards

Performance benchmarks or criteria that are established based on average or anticipated conditions for the purpose of budgeting and cost control.

Labour Efficiency Variance

A measure that calculates the difference between the expected labor hours to produce an output and the actual hours used.

Poor Quality Materials

Materials that do not meet the required standards or specifications, potentially leading to failures in production or the final product.

Production Manager

A professional responsible for overseeing the production process, ensuring efficiency, meeting production targets, and maintaining quality standards.

Q6: When using activity-based costing, the cost associated

Q29: Refer to Exhibit 19-5. Given the

Q41: Use the following information to prepare a

Q62: As fixed costs increase, the break-even point

Q74: Tulip Company is a tulip bulb distributor.

Q82: The type of center that is evaluated

Q83: Costs incurred for the benefit of more

Q85: CharCore mixes together wood chips and pine

Q89: Michele has a salary of $56,000 per

Q99: The MEC Company has two divisions: the