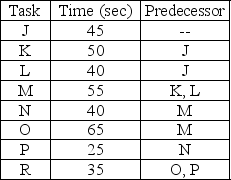

The process design team at a manufacturer has broken an assembly process into eight basic steps,each with a required time,and predecessor as shown in the table.There are 8 productive hours available in a day and the manufacturer wishes to produce 400 units using seven workers-one for each station.

Balance the line according to the longest operation rule and calculate the percent idle time.Using the same arrangement of tasks at work stations,what is the greatest output that can be achieved in an eight-hour day and what is the percent idle time of this design?

Balance the line according to the longest operation rule and calculate the percent idle time.Using the same arrangement of tasks at work stations,what is the greatest output that can be achieved in an eight-hour day and what is the percent idle time of this design?

Definitions:

Q16: A reverse logistics system handles repairs,recycling,returns and

Q16: Single sourcing is a better choice than

Q17: After calculating the applicant's credit score,the system

Q19: Multiple regression was used to forecast success

Q21: An arrow in a process map represents

Q34: The ratio of earnings to sales for

Q37: Which of these is NOT a component

Q39: Define logistics and explain why it is

Q63: Monte Carlo simulation uses statistical sampling to

Q142: Is fiscal policy more or less effective