Jamestown Furniture Co. is a small, but fast-growing manufacturer of living room furniture. Its two principal products are end tables and sofas. There are five processes in the manufacturing at Jamestown: Cutting the lumber, cutting the fabric, sanding, staining, and assembly. Jamestown has one employee working in fabric cutting and one employee working in staining. These are relatively skilled workers, and could be replaced only with some difficulty. The cutting and sanding operations are performed by two workers each, and while there is some skill to these operations, it is less critical than for staining and for fabric cutting. Assembly is the least skill-based process, and is currently done by one full-time employee and a group of part timers who provide a total of 175 minutes of working time per week. The other employees work a 40 hour week, with 5 hours off for breaks, training, and personal time. Assume a four week month, and that by prior agreement, any of the employees can be switched from one task to another. The current demand for Jamestown's products and sales prices are provided below. Jamestown expects demand to increase significantly in the coming months (this depends on whether it is able to successfully obtain the order it is negotiating to get from a motel chain). The materials cost for the table is $150 and $275 for the sofa.  The time required for each activity and the total time available are shown below.

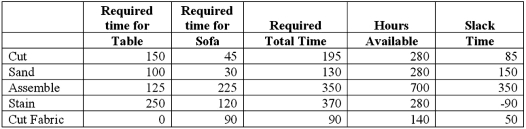

The time required for each activity and the total time available are shown below.  Required:

Required:

What is the most profitable production plan for Jamestown? Explain your answer with supporting calculations.

Definitions:

Alpha Particles

A type of ionizing radiation consisting of two protons and two neutrons; they are a common form of particles emitted by radioactive materials.

Gamma Rays

Electromagnetic radiation of the highest frequency and energy, emitted from atomic nuclei during radioactive decay.

Background Radiation

The ionizing radiation present in the environment naturally from cosmic rays, radon gas, and other sources not due to deliberate human activity.

Radon

A radioactive, colorless, odorless noble gas occurring naturally as the decay product of uranium, posing health risks due to its ionizing radiation.

Q1: If Johnson determines price using a 20%

Q17: If I = the cost of conducting

Q23: A characteristic of the payback method (before

Q27: How many units of the product were

Q30: What is the overhead production volume variance

Q47: Done on a regular basis, relevant cost

Q66: The total overhead flexible-budget (FB) variance for

Q85: The standard variable overhead application rate per

Q115: A standard costing system will produce the

Q174: The total standard direct labor cost for