Elisko Inc. is a major book distributor. Elisko's Shipping Department consists of a manager plus ten other permanent positions- four supervisors and six loaders. The four supervisors and six loaders provide the minimum staff and frequently must be supplemented by additional workers, especially during the weeks when the volume of shipments is heavy. Thus, the number of people shipping the orders frequently averages over 30 per week, i.e., ten permanent persons plus 20 temporary workers. The temporary workers are hired through a local agency. Elisko must use temporary workers to maintain a minimum daily shipment rate of 95 percent of orders presented for shipping. The loss of efficiency from using temporary workers is minimal, and the $10.00 per hour cost of temporary workers is less than the $15.00 per hour for the loaders and $22.50 per hour for the supervisors on Elisko's permanent staff. The agency requires Elisko to utilize each temporary worker for at least four hours each day.

Jim Locter, Shipping Manager, schedules temporary help based on forecasted orders for the coming week. Supervisors serve as loaders until temporary help is needed. A supervisor stops loading when the ratio of loaders to supervisors reaches 7: 1. Locter knows that he will need temporary help when the forecasted average daily orders exceed 300. Locter has frequently requested from two to four extra temporary workers per day to guard against unexpected rush orders. If there was not enough work, he would dismiss the extra people at noon after four hours of work.

The agency has not been pleased with Locter's practice of overhiring and has notified Elisko that it is changing its policy. From now on, if a person is dismissed before an eight-hour assignment is completed, Elisko will still be charged for an eight-hour day plus mileage back to the agency for reassignment. This policy would go into effect the following week.

Paula Brand, General Manager, called Jim Locter to her office when she received the notice from the agency. She told Locter, "Your staffing has to be better. This penalty could cost us up to $300-$500 per week in labor cost for which we receive no benefit. Why can't you schedule better?"

Locter replied, "I agree that the staffing should be better, but I can't do it accurately when there are rush orders. By being able to layoff people at noon, I have been able to adjust for the uncertain order schedule without cost to the company. Of course the agency's new policy changes this."

Locter and Brand contacted Elisko's Controller, Mitch Berg regarding Locter's problem on how to estimate the number of people needed each week. Berg reasoned that Locter needed a quick solution until he could study the work flow. Berg suggested a regression analysis using the number of orders shipped as the independent variable and the number of workers (permanent plus temporary) as the dependent variable. Berg indicated that data for the past year was available and that the analysis could be done quickly using the accounting department's computer system.

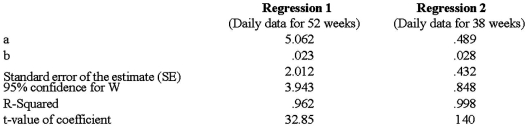

Berg completed the two regression analyses that are presented below. The first regression was based on the data for the entire year. The second regression excluded the weeks when only the 10 permanent staff persons were used; these weeks were unusual and appeared to be out of the relevant range.

Locter was not familiar with regression analysis and, therefore, was unsure how to implement this technique. He wondered which regression data he should employ, i.e., which one was better. When he recognized that the regression was based on actual orders shipped by week, Berg told him he could use the forecasted shipments for the week to determine the number of workers needed.

Regression Equation:

W = a + bS

S = orders shipped

Required:

Required:

(1) Using Regression 1 based on data from a full year, calculate the number of temporary workers Jim Locter would plan to hire for a forecast indicating 1,200 shipments per day.

(2) Which one of the two regressions appears to be better? Explain your answer.

(3) Explain the circumstances under which Jim Locter can use the regression in his planning for temporary workers.

(4) Explain whether the regression analysis that Elisko Inc. employed in this situation could be improved. If it cannot be improved, explain why.

(5) How can the regression analysis help Elisko be more competitive?

Definitions:

Rent Expense

The cost incurred for renting property or equipment used in business operations, recognized as an expense on the income statement.

Product Cost

encompasses all expenses directly involved in the manufacturing of a product, including raw materials, labor, and overhead.

Factory Overhead Cost

Expenses related to operating a factory that are not directly tied to individual products, including utilities, rent, and maintenance of machinery.

Materials Used

The raw materials and components consumed in the process of manufacturing finished goods.

Q3: Cost allocation of shared facilities cost is

Q9: Budgeting provides all of the following except:<br>A)A

Q20: X Company's degree of operating leverage (DOL)

Q51: Powell Company uses a job costing system.

Q64: Assuming that Product Line C is discontinued

Q65: The sales in units required by Framing

Q95: The total cost accumulated in the marketing

Q100: The degree of operating leverage (DOL) at

Q102: The variable Y in the equation is

Q111: The major problem with relevant cost determination