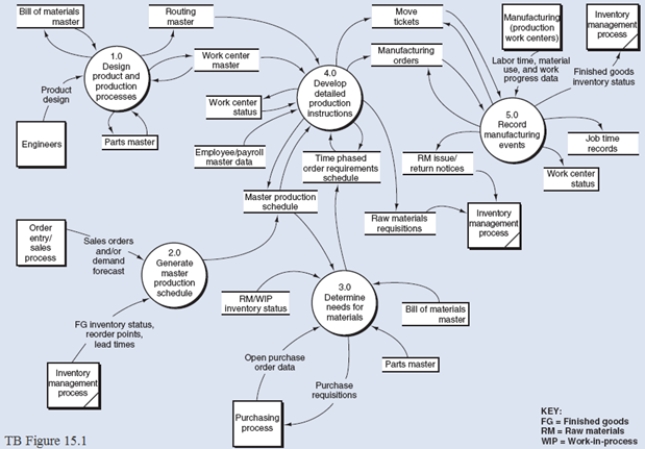

The process within TB Figure 15.1 Bubble 1.0 might be described as follows: Consistent with the value chain concept, the IPP begins with the design of the product and production processes. Activity-based costing can be used to develop estimates of the future cost of producing new products as well as potential cost changes from product or design changes. The entire design process is automated through the use of computer-aided design (CAD) and computer-aided engineering (CAE). With the use of enterprise systems, the electronic designs produced using CAD/CAE become the basis for developing detailed production schedules (bubble 2.0 in TB Figure 15.1) as well as the electronic control of production machines. In addition to the detailed product design, the CAD/CAE process results in several data stores of information that are used later in the IPP:

*Bill of materals (BOM) master: The BOM provides the basis far later arders of raw materials (bubble 3.0 in TB Figure 15.1) when a firished good is to be produced. *Partmaster: The parts master ar raw materials inventory master lists the detailed specifications of each raw materials item. An enpineer must specify the information for the new material in the parts master when anew part is used in product design. Often, existing parts will be used in new products to reduce needed ardering and caryying costs far the inventary.

*Rauting master: The rauting master 5pecifes the aperations neces.ary to complete a subas5embly or firished good, and the secquence of these operations. The ruuting mester alsa includes the machiring tolerances; the tools, jig5, and fixtures reqquired and the time allowed far each aperation. The rauting master is vital to developing detailed prodiction instructians (bubble 4.0 in TB Figure 15.1). Camputer aided pracess planring (CAPP), is aften used in develaping the rauting master far develaping new products. CAPP is an autamated decision support system that generates manufacturing aperations instructions and rauting5 based an infarmation about machinery requirements and capabilities.

*Wark center master: The wark center master describes each wark center available far producing products. A wark statian is the a5signed locatian where a warker perfarms their jab. A graup of simular wark stations canstitutes a wark center. When new praducts requure new machines ar production activites, a new recard in the wark center master muft be created. Refer to TB Figure 15.1. Prepare a Level 1 data flow diagram for the product and production process design process only.

Definitions:

Gain on Sale

The financial profit gained from selling an asset for more than its book value.

Opening Retained Earnings

The amount of retained earnings at the beginning of a financial period, representing the accumulated profits that have not been distributed to shareholders as dividends.

Revaluation Model

An accounting method that allows for the upward or downward adjustment in the carrying amount of an asset to its current fair value, provided it can be measured reliably.

Revaluation Increment

An increase in the book value of an asset to reflect its fair value, often recognized during asset revaluation processes.

Q7: _ are particular Web sites or portals

Q19: Which is true about protein A?<br>A)It binds

Q24: Formation of biofilms attached to fibronectin and

Q28: _ authorize and record movement of a

Q30: In which role might the accountant be

Q30: When the vendor payment is made, the

Q50: Which of the following has responsibilities and

Q73: As used in the text, the term

Q80: The _ data maintains data concerning an

Q129: After the vendor has been selected, the