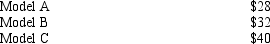

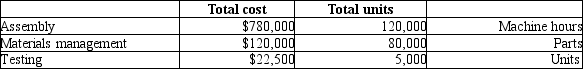

Orlando Avionics makes three types of radios for small aircraft-model A, model B, and model C. The manufacturing operations are mechanized and there is no direct labor. Manufacturing overhead costs are significant, and Orlando has adopted an activity-based costing system. Direct materials costs per unit for each model are as follows:  Orlando has three activities-assembly, materials management, and testing. The cost driver for assembly is machine hours. The cost driver for materials management is number of parts, and the cost driver for testing is the number of units of product. Total costs and production volumes for the year 2012 were estimated as follows:

Orlando has three activities-assembly, materials management, and testing. The cost driver for assembly is machine hours. The cost driver for materials management is number of parts, and the cost driver for testing is the number of units of product. Total costs and production volumes for the year 2012 were estimated as follows: The Model A radio requires 12 parts to construct, and also requires 16 machine hours of processing. What is the manufacturing cost to make one unit of Model A?

The Model A radio requires 12 parts to construct, and also requires 16 machine hours of processing. What is the manufacturing cost to make one unit of Model A?

Definitions:

Emotions

Complex reactions to internal or external events involving subjective feelings, physiological arousal, and observable behavior.

Motor Skills

The abilities required to control and coordinate the movements of the muscles in the body.

Passions

Intense emotions or desires that drive individuals to pursue specific interests or activities.

Sleep Pattern

The natural rhythm of sleep and wakefulness, indicating when and how long a person sleeps, which can vary by age and lifestyle.

Q5: Repair and maintenance costs of vehicles used

Q7: When materials are requisitioned for a job,

Q31: Simms Manufacturing is considering two alternative investment

Q36: The engineering firm of Dobbs and Smith

Q44: Full-product cost includes all manufacturing costs plus

Q71: Action Products is deciding whether to outsource

Q97: Burr Hill golf course is planning for

Q100: Horizontal analysis compares each item in the

Q138: Clark Manufacturing makes blank CDs; it is

Q155: Which of the following statements is CORRECT