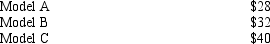

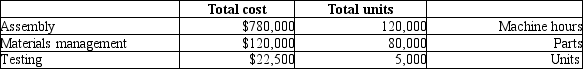

Orlando Avionics makes three types of radios for small aircraft-model A, model B, and model C. The manufacturing operations are mechanized and there is no direct labor. Manufacturing overhead costs are significant, and Orlando has adopted an activity-based costing system. Direct materials costs per unit for each model are as follows:  Orlando has three activities-assembly, materials management, and testing. The cost driver for assembly is machine hours. The cost driver for materials management is number of parts, and the cost driver for testing is the number of units of product. Total costs and production volumes for the year 2012 were estimated as follows:

Orlando has three activities-assembly, materials management, and testing. The cost driver for assembly is machine hours. The cost driver for materials management is number of parts, and the cost driver for testing is the number of units of product. Total costs and production volumes for the year 2012 were estimated as follows: The Model B radio requires 15 parts to construct, and also requires 18 machine hours of processing. What is the manufacturing cost to make one unit of Model B?

The Model B radio requires 15 parts to construct, and also requires 18 machine hours of processing. What is the manufacturing cost to make one unit of Model B?

Definitions:

mRNA

Messenger RNA, a form of RNA that transfers genetic instructions from DNA to the ribosome for protein synthesis.

Codon

A sequence of three nucleotides in mRNA that specifies a particular amino acid or termination signal during protein synthesis.

Amino Acid

Organic molecules that serve as the building blocks of proteins, containing both an amino group and a carboxyl group.

Coding Region

A portion of a gene's DNA or RNA that codes for protein.

Q8: The variable cost per unit is assumed

Q55: On June 30, Coraline Company finished job

Q64: Please review the information on 4 potential

Q107: A small business produces a single product

Q123: Simms Manufacturing is considering two alternative investment

Q139: When a business is considering whether to

Q145: Please refer to the following data concerning

Q150: If all other factors are constant, an

Q155: Managers' decisions are based primarily on quantitative

Q163: If variable costs go up, and all