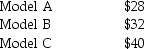

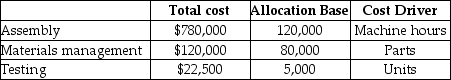

Orlando Avionics makes three types of radios for small aircraft-Model A,Model B,and Model C.The manufacturing operations are mechanized and there is no direct labor.Manufacturing overhead costs are significant,and Orlando has adopted an activity-based costing system.Direct materials costs per unit for each model are as follows:  Orlando has three activities-assembly,materials management,and testing.The cost driver for assembly is machine hours.The cost driver for materials management is the number of parts,and the cost driver for testing is the number of units of product.Total costs and production volumes for the year 2015 were estimated as follows:

Orlando has three activities-assembly,materials management,and testing.The cost driver for assembly is machine hours.The cost driver for materials management is the number of parts,and the cost driver for testing is the number of units of product.Total costs and production volumes for the year 2015 were estimated as follows: The Model A radio requires twelve parts to construct,and requires 16 machine hours of processing.What is the manufacturing cost to make one unit of Model A?

The Model A radio requires twelve parts to construct,and requires 16 machine hours of processing.What is the manufacturing cost to make one unit of Model A?

Definitions:

Deposits Reserve

Funds that banks are required to hold in reserve, either in their vaults or at a central bank, as a safeguard against bank runs and to ensure liquidity.

Greenbacks

A term historically used to refer to paper currency issued by the United States during the Civil War, recognized by their green coloring.

Gold Standard

A monetary system in which the value of a country's currency is directly linked to gold, ensuring stability and trust in the currency.

Time Deposits

A financial product provided by banks that offers a higher interest rate in exchange for keeping a specified amount of money untouched for a predetermined period.

Q12: The traditional income statement format is prepared

Q13: Merchandiser's inventory consists of raw materials inventory,work-in-process

Q43: Absorption costing is the only method used

Q51: Activity-based costing focuses on a single predetermined

Q56: Edge Inc.had two products-Le Chaud and Le

Q66: Costs incurred on goods sold are transferred

Q81: Cost amounts that are transferred out of

Q99: What is the cost per line

Q119: A company is considering spending the following

Q120: Activity-based costing uses a common allocation base