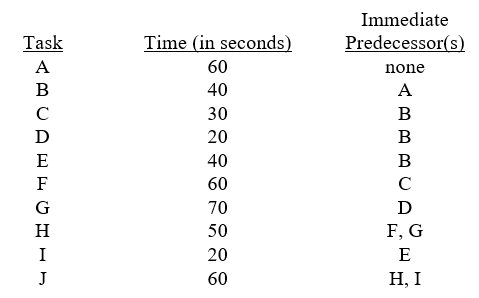

The Florida Appliance Company is installing an assembly line to produce vacuum cleaners, and you, as an operations manager, are responsible for balancing the line.The tasks to be performed are listed, along with their times and immediate predecessors. The company is planning to operate 2 shifts per day, 8 hours per shift.The desired output rate of the line is 480 units per day.

The company is planning to operate 2 shifts per day, 8 hours per shift.The desired output rate of the line is 480 units per day.

a.Compute the cycle time per unit in minutes.

b.Compute the minimum number of workstations required.

c.Use the longest-task-time heuristic to balance the assembly line.

d.Compute the efficiency of your assembly line.

Definitions:

Population Density

The number of individuals of a species per unit of area or volume at a given time.

Individuals

Separate and distinct organisms or entities, often used in the context of discussing a single member of a species.

Natural Selection

The process by which traits become more or less common in a population due to consistent effects upon the survival or reproduction of their bearers.

Adaptive Changes

Adjustments or modifications in organisms or populations that enhance their survival and reproductive success in a particular environment.

Q15: Considering ergonomics, which of the following does

Q33: A company makes traffic signals for downtown

Q43: If actual demand for a product is

Q44: The quote "Happy employees create happy customers"

Q55: A strategy for increasing long-term capacity in

Q58: A pathway is a route that a

Q59: The objective of assembly line balancing is

Q68: When demand is seasonal, inventory cannot be

Q76: Virtual teams are empowered work teams that

Q81: Define reliability.Include the four major elements.