Moss Point Manufacturing has just completed a major change in its quality control (QC)process.Previously,products had been reviewed by QC inspectors at the end of each major process,and the company's ten QC inspectors were charged as direct labor to the operation or job.In an effort to improve efficiency and quality,a computer video QC system was purchased for $250,000.The system consists of a minicomputer,15 video cameras,other peripheral hardware,and software.

The new system uses cameras stationed by QC engineers at key points in the production process.Each time an operation changes or there is a new operation,the cameras are moved,and a new master picture is loaded into the computer by a QC engineer.The camera takes pictures of the unit in process,and the computer compares them to the picture of a "good" unit.Any differences are sent to a QC engineer who removes the bad units and discusses the flaws with the production supervisors.The new system has replaced the 10 QC inspectors with two QC engineers.

The operating costs of the new QC system,including the salaries of the QC engineers,have been included as factory overhead in calculating the company's plant-wide factory overhead rate,which is based on direct labor dollars.

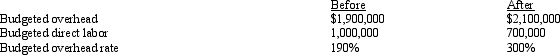

The company's president is confused.His vice president of production has told him how efficient the new system is,yet there is a large increase in the factory overhead rate.The computation of the rate before and after is shown below.

"Three hundred percent," lamented the president."How can we compete with such a high factory overhead rate?"

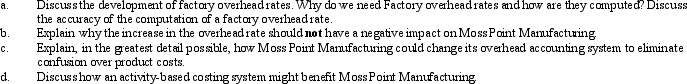

REQUIRED:

Definitions:

Sustainability

Practices and strategies for maintaining ecological balance by avoiding depletion of natural resources.

Balance

An equilibrial state where different elements are in the correct proportions or positions, often used figuratively to denote a well-proportioned mix of work, life, and activities.

Incremental Sustainable Change

Gradual and continuous modifications implemented in an organization or system that aim to improve sustainability without disrupting existing processes significantly.

Transition Phases

Transition phases refer to periods of change or transformation within an organization or an individual's life, often marked by developments or adjustments to new conditions.

Q4: The cost analyst must consider on a

Q26: Computing equivalent units (Appendix 2.1).The Assembly Department

Q27: Which of the following is true about

Q32: Dukes Computing Systems<br>Dukes Computing Systems manufactures and

Q39: The following information was received from Fort

Q46: The value chain ends with which of

Q87: Quality improvement.Designer Frames makes bicycle frames in

Q89: Which of the following are components of

Q102: Which statement is true concerning decentralization?<br>A)Decentralization impedes

Q104: Which of the following is not usually