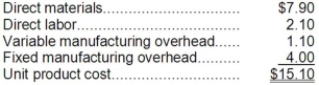

Teich Inc. is considering whether to continue to make a component or to buy it from an outside supplier. The company uses 15,000 of the components each year. The unit product cost of the component according to the company's absorption cost accounting system is given as follows:  Assume that direct labor is a variable cost. Of the fixed manufacturing overhead, 10% is avoidable if the component were bought from the outside supplier; the remainder is not avoidable. In addition, making the component uses 3 minutes on the machine that is the company's current constraint. If the component were bought, time would be freed up for use on another product that requires 6 minutes on this machine and that has a contribution margin of $8.10 per unit. When deciding whether to make or buy the component, what cost of making the component should be compared to the price of buying the component?

Assume that direct labor is a variable cost. Of the fixed manufacturing overhead, 10% is avoidable if the component were bought from the outside supplier; the remainder is not avoidable. In addition, making the component uses 3 minutes on the machine that is the company's current constraint. If the component were bought, time would be freed up for use on another product that requires 6 minutes on this machine and that has a contribution margin of $8.10 per unit. When deciding whether to make or buy the component, what cost of making the component should be compared to the price of buying the component?

Definitions:

Confidence Interval

A span of values, obtained from sample information, which is expected to encompass the value of an unidentified population characteristic.

Mean

The arithmetic average of a set of values, calculated by adding all the numbers together and dividing by the count of values.

Standard Deviation

A measure of the amount of variation or dispersion of a set of values, showing how much the values differ from the mean.

Mean

The average of a set of numerical values, calculated as the sum of the values divided by the number of values.

Q20: Poor quality materials could have an unfavorable

Q27: Albert Manufacturing Company manufactures a single product.

Q44: Omary Corporation has a standard cost system

Q52: Northern Stores is a retailer in the

Q55: Gierlach Beet Processors, Inc., processes sugar beets

Q55: An increase in accrued liabilities of $1,000

Q62: The fixed manufacturing overhead volume variance for

Q74: For the past year, the minimum required

Q97: The fixed manufacturing overhead budget variance for

Q163: Ramon Corporation makes 18,000 units of part