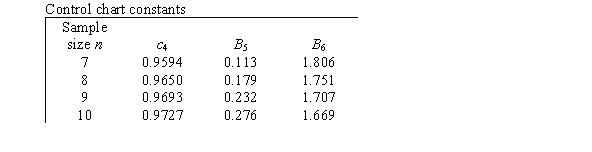

Parts manufactured by an injection molding process are subjected to a compressive strength test.We wish to monitor the compressive strength of the parts manufactured by this process using both  and s charts.Samples of size 9 are to be taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The target values for the compressive strengths are a mean of = 80 psi and a standard deviation of = 3 psi.The control chart constants are (partially) reproduced below.

and s charts.Samples of size 9 are to be taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The target values for the compressive strengths are a mean of = 80 psi and a standard deviation of = 3 psi.The control chart constants are (partially) reproduced below.  What is the lower control limit for the

What is the lower control limit for the

Chart?

Definitions:

Mathematical Formula

A concise way of expressing information symbolically or a rule for calculating numerical values based on certain mathematical operations.

Standard Deviation

A measure of the amount of variation or dispersion of a set of values; a high standard deviation indicates greater variability.

Standard Normal Distribution

A normal distribution with a mean of 0 and a standard deviation of 1, used in z-score calculations to determine probabilities.

Normal Distribution

A statistical distribution which is evenly spread around the mean, indicating that occurrences close to the mean are more common than those further away.

Q3: If you draw an M&M candy at

Q6: The number of undergraduates at Johns Hopkins

Q8: In logistic regression,there can be _ explanatory

Q14: When performing a t procedure,it is best

Q20: In this experiment,the risk-taking propensity of 90

Q30: When we state the alternative hypothesis to

Q33: A study was done to determine whether

Q39: Thirty random students are selected and asked

Q46: The scores of individual students on the

Q77: Data were obtained in a study of