Parts manufactured by an injection molding process are subjected to a compressive strength test.We monitor the compressive strength of the parts manufactured by this process using an  and an s control chart.Samples of size 9 are taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The overall mean of the sample means is

and an s control chart.Samples of size 9 are taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The overall mean of the sample means is  = 81.2 psi,and the mean of the sample standard deviations is

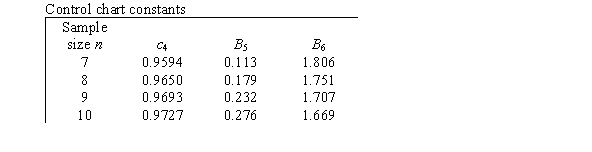

= 81.2 psi,and the mean of the sample standard deviations is  = 2.9 psi.The control chart constants are (partially) reproduced below.

= 2.9 psi.The control chart constants are (partially) reproduced below.  What is the value of the center line for the

What is the value of the center line for the  chart?

chart?

Definitions:

Nonsystematic Variance

The portion of an asset's total variance that is attributable to factors unique to that specific asset, as opposed to broader market influences.

Market Index

A metric that measures the performance of a basket of securities intended to represent a particular market or segment of it, like the S&P 500 or NASDAQ.

Treynor-Black Model

A portfolio optimization model that integrates market equilibrium theory with security selection to enhance portfolio performance.

Nonsystematic Risk

The risk associated with an individual asset or company, which can be reduced through diversification, unlike systematic risk.

Q1: Consider the following graphic results from a

Q6: The following scatter plot and SPSS output

Q16: The number of undergraduates at Johns Hopkins

Q17: Malaria is a leading cause of infectious

Q33: What is an R chart used for?<br>A)To

Q38: In a study on scholastic test scores

Q47: A study compares the average number of

Q57: A recent study was done to assess

Q59: There is an old saying in golf:

Q79: In a certain game you have to