Parts manufactured by an injection molding process are subjected to a compressive strength test.We monitor the compressive strength of the parts manufactured by this process using an  and an s control chart.Samples of size 9 are taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The overall mean of the sample means is

and an s control chart.Samples of size 9 are taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The overall mean of the sample means is  = 81.2 psi,and the mean of the sample standard deviations is

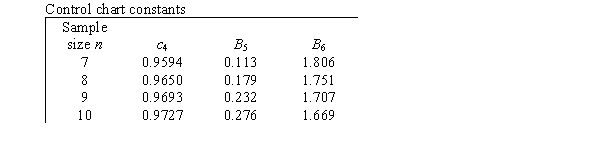

= 81.2 psi,and the mean of the sample standard deviations is  = 2.9 psi.The control chart constants are (partially) reproduced below.

= 2.9 psi.The control chart constants are (partially) reproduced below.  What is the lower control limit for the

What is the lower control limit for the  chart?

chart?

Definitions:

Ethical Dilemmas

Situations where individuals must choose between competing moral principles or values, often occurring in professional settings and requiring careful consideration and judgment.

Cultural Differences

Variations in the beliefs, values, habits, and practices of individuals from different backgrounds, which can impact international business and marketing strategies.

Ethical Standards

The principles and values that guide the behavior of individuals and organizations, ensuring conduct that is honest, fair, and respectful to all stakeholders.

Directional Code

A sequence of numbers or letters used to guide or provide directions, commonly seen in postal addresses, maps, or as part of navigational aids.

Q11: The data below represent the means from

Q19: Suppose that A and B are two

Q26: If you draw an M&M candy at

Q28: "Cramming" is a technique often used by

Q31: Does income increase when you get married?

Q39: A study compares six groups with five

Q42: To use a log transformation,all values must

Q43: The statistical model for linear regression can

Q59: There is an old saying in golf:

Q63: Piston rings for an automotive engine are