Parts manufactured by an injection molding process are subjected to a compressive strength test.We monitor the compressive strength of the parts manufactured by this process using an  and an s control chart.Samples of size 9 are taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The overall mean of the sample means is

and an s control chart.Samples of size 9 are taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The overall mean of the sample means is  = 81.2 psi,and the mean of the sample standard deviations is

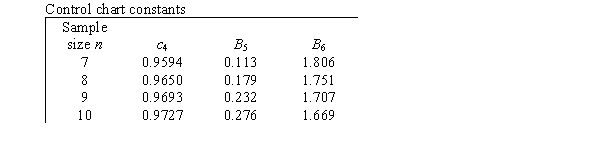

= 81.2 psi,and the mean of the sample standard deviations is  = 2.9 psi.The control chart constants are (partially) reproduced below.

= 2.9 psi.The control chart constants are (partially) reproduced below.  What is the lower control limit for the

What is the lower control limit for the  chart?

chart?

Definitions:

Activity Duration

The time period from the start to the end of an activity or task.

Early Finish

In project management, the earliest possible point in time when a task or project phase can be completed, assuming all goes according to plan.

Late Start

The latest possible time a task can begin without delaying the project completion date in project management.

Activity Duration

The total length of time required to complete a specific task or activity from start to finish.

Q2: A study was conducted in a large

Q9: The data referred to in this question

Q16: The number of undergraduates at Johns Hopkins

Q26: To investigate whether or not sending text

Q33: When ranking observation from smallest to largest

Q34: A study,conducted by Jackson et al.and published

Q57: Parts manufactured by an injection molding process

Q88: The distribution of GPA scores is known

Q88: Malaria is a leading cause of infectious

Q92: Which of the following best describes what