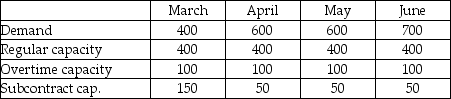

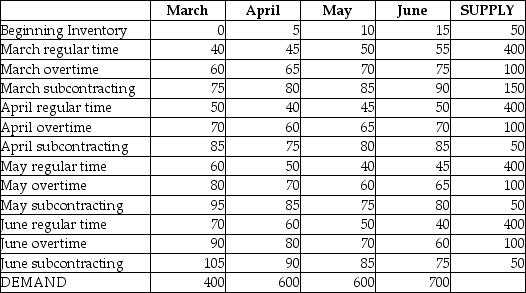

Byron's Manufacturing makes tables.Demand for the next four months and capacities of the plant are shown in the table below.Unit cost on regular time is $40.Overtime cost is 150% of regular time cost.Subcontracting is available in substantial quantity at $75 per unit.Holding costs are $5 per table per month;back orders cost the firm $10 per unit per month.Byron's management believes that the transportation algorithm can be used to optimize this scheduling problem.The firm has 50 units of beginning inventory and anticipates no ending inventory.

Answer the following questions based on the data table and solution table shown below.

Answer the following questions based on the data table and solution table shown below.

Byron's Manufacturing

Byron's Manufacturing Solution

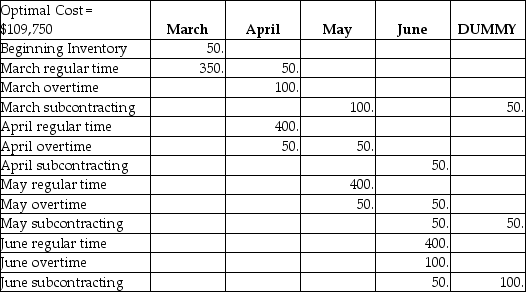

Byron's Manufacturing Solution

a.How many units will be produced on regular time in June?

a.How many units will be produced on regular time in June?

b.How many units will be produced by subcontracting over the four-month period?

c.What will be the inventory at the end of April?

d.What will be total production from all sources in April?

e.What will be the total cost of the optimum solution?

f.Does the firm utilize the expensive options of subcontracting and back ordering? When;why?

Definitions:

Binary Relation

A mathematical concept describing a relation between two elements, typically in the context of sets.

Reflexive

pertains to relations where an element is always related to itself, or in social theories, where actions or processes mirror and affect each other within a system.

Transitive

In mathematics and logic, transitive refers to a relation where if relation A exists between B and C, and relation A exists between C and D, then the relation must also exist between B and D.

Complete

In a market context, it refers to a situation where there is sufficient information and resources for transactions to occur without any barriers.

Q15: Low-level coding means that:<br>A)a final item has

Q16: A furniture maker has delivered a dining

Q50: What are time fences? Why are they

Q63: What is the formula for the bullwhip

Q71: What is the priority rule that sequences

Q78: A dependent demand item is so called

Q82: Which of the following statements regarding the

Q106: Daily usage of an assembly is 100

Q114: Which of the following would NOT be

Q158: The Winfield Distributing Company has maintained an