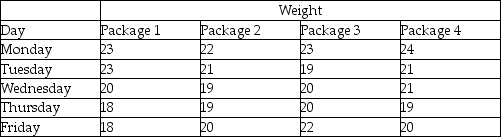

A quality analyst wants to construct a sample mean chart for controlling a packaging process.He knows from past experience that the process standard deviation is two ounces.Each day last week,he randomly selected four packages and weighed each.The data from that activity appear below.

(a)Calculate all sample means and the mean of all sample means.

(a)Calculate all sample means and the mean of all sample means.

(b)Calculate upper and lower 2-sigma x-bar chart control limits that allow for natural variations.

(c)Based on the x-bar chart,is this process in control?

Definitions:

Labor Efficiency Variance

The difference between the actual hours worked and the standard hours expected to produce a certain amount of output, multiplied by the standard labor rate.

Variable Overhead Rate Variance

The difference between the actual variable overhead incurred and the expected overhead based on standard rates.

Variable Overhead Efficiency Variance

The difference between the actual variable overhead incurred and the standard cost allotted for the actual production achieved, indicating the efficiency of utilizing variable resources.

Materials Quantity Variance

The difference between the actual quantity of materials used in production and the expected quantity, valued at standard cost.

Q5: A city police chief decides to do

Q25: What are the differences between quantitative and

Q29: Which of the following statements regarding "proximity"

Q30: _ forecasts are concerned with rates of

Q43: Value analysis takes place:<br>A)when the product is

Q44: One fundamental difference between a process chart

Q49: An improvement in quality must necessarily increase

Q94: A(n)_ divides a project into more and

Q101: An assembly drawing:<br>A)shows,in schematic form,how the product

Q105: Group technology requires that:<br>A)each component be identified