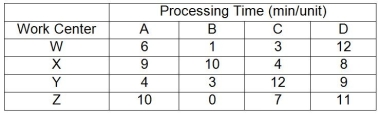

Table 7.5

A company makes four products that have the following characteristics: Product A sells for $50 but needs $10 of materials and $15 of labor to produce;Product B sells for $75 but needs $30 of materials and $15 of labor to produce;Product C sells for $100 but needs $50 of materials and $30 of labor to produce;Product D sells for $150 but needs $75 of materials and $40 of labor to produce.The processing requirements for each product on each of the four machines are shown in the table.  Work centers W,X,Y,and Z are available for 40 hours per week and have no setup time when switching between products.Market demand for each product is 80 units per week.In the questions that follow,the traditional method refers to maximizing the contribution margin per unit for each product,and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

Work centers W,X,Y,and Z are available for 40 hours per week and have no setup time when switching between products.Market demand for each product is 80 units per week.In the questions that follow,the traditional method refers to maximizing the contribution margin per unit for each product,and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

-Use the information in Table 7.5.Using the traditional method,in what sequence should products be scheduled for production?

Definitions:

Direct Labor Hours

The cumulative hours that employees, who are directly engaged in the creation of products or services, have worked.

Overhead Rate

A calculation used to allocate indirect costs to products or services, typically expressed as a percentage of direct labor, materials, or another base.

Activity-based Costing

A costing method that assigns overhead and indirect costs to specific products or activities based on their use of resources.

Allocation Base

A criterion or standard used to distribute costs across multiple cost objects.

Q22: A _ is the difference between demand

Q32: The advantage of variable measurements is that

Q37: Capacity decisions should be made separately from

Q55: Use the information in Table 6.5.What action,if

Q70: The best example of a finite customer

Q88: Which one of the following statements about

Q118: Use the information in Scenario B.4.What is

Q124: Expand both tablet manufacturing and packaging at

Q138: The central line on a p-chart is

Q184: Setup cost is independent of order size.