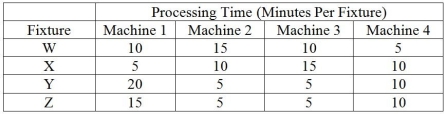

Table 7.8

King Supply makes four different types of plumbing fixtures: W,X,Y and Z.The contribution margins for these products are: $70 for Product W,$60 for Product X,$90 for Product Y and $100 for Product Z.Fixed overhead is estimated at $5,500 per week.The manufacture of each fixture requires four machines,Machines #1,2,3 and 4.Each of the machines is available for 40 hours a week and there is no setup time required when shifting from the production of one product to any other.The processing requirements to make one unit of each product are shown in the table.Weekly product demand for the next planning period has been forecasted as follows: 70 Ws,60 Xs,50 Ys and 30 Zs.  In the questions that follow,the traditional method refers to maximizing the contribution margin per unit for each product,and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

In the questions that follow,the traditional method refers to maximizing the contribution margin per unit for each product,and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

-Use the information in Table 7.8.Which machine is the bottleneck operation?

Definitions:

Deductions

Specific amounts subtracted from gross income to reduce the taxable income, including allowances, expenses, and exemptions.

Voucher Register

A journal that records all vouchers once they are approved, which includes amounts to be paid, to whom, and the accounts affected.

Approved Vouchers

Documents that have been verified and authorized for payment because they accurately reflect the goods or services received.

Bank Reconciliation

The process of matching and comparing figures from accounting records against those presented on a bank statement to ensure accuracy.

Q20: Depict the expansionist strategy graphically as a

Q23: A newsstand is trying to determine how

Q42: Reducing setup costs will increase the pressure

Q61: Use the information in Scenario 9.13.What reorder

Q75: A competent operations manager should first eliminate

Q104: _ inventory is the portion of total

Q107: The number of setups (or orders)per year

Q124: Expand both tablet manufacturing and packaging at

Q131: Use the information in Table 7.8.Using the

Q185: Which step of the Six Sigma DMAIC