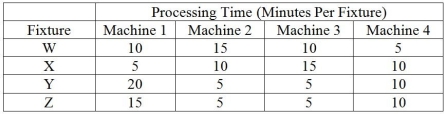

Table 7.8

King Supply makes four different types of plumbing fixtures: W,X,Y and Z.The contribution margins for these products are: $70 for Product W,$60 for Product X,$90 for Product Y and $100 for Product Z.Fixed overhead is estimated at $5,500 per week.The manufacture of each fixture requires four machines,Machines #1,2,3 and 4.Each of the machines is available for 40 hours a week and there is no setup time required when shifting from the production of one product to any other.The processing requirements to make one unit of each product are shown in the table.Weekly product demand for the next planning period has been forecasted as follows: 70 Ws,60 Xs,50 Ys and 30 Zs.  In the questions that follow,the traditional method refers to maximizing the contribution margin per unit for each product,and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

In the questions that follow,the traditional method refers to maximizing the contribution margin per unit for each product,and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

-Use the information in Table 7.8.Using the bottleneck method,in what sequence should products be scheduled for production?

Definitions:

Proportion Of Defectives

The ratio or percentage of defective items in a batch or production process, indicating the quality or reliability of the manufacturing process.

Specifications

Detailed descriptions of the requirements, characteristics, or standards that an item, project, or process must meet.

Pooled Standard Deviation

A method to estimate the standard deviation across different samples or groups by combining their variances, assuming they have the same variance.

Control Limit

The upper and lower bounds on a control chart in statistical process control that signal when a process might be out of control or requires investigation.

Q23: What are the assumptions of the exponential

Q25: A plant's manufacturing process has a takt

Q37: In the single-server model the:<br>A)customers are assumed

Q44: A plant's manufacturing process has a takt

Q51: A larger capacity cushion may be required

Q52: A(n)_ occurs when a customer order cannot

Q88: Which one of the following statements about

Q114: What are the components of holding cost?

Q157: Use the information in Scenario 9.2.How many

Q182: Use the information in Scenario 9.1.What are