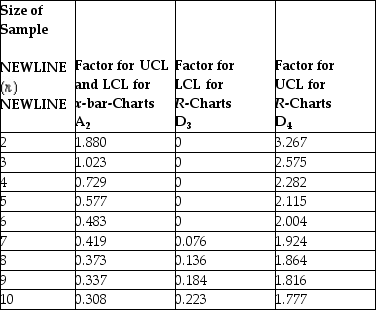

Table 5.1

Factors for Calculating Three-Sigma Limits for the  Chart and R-Chart

Chart and R-Chart

Source: 1950 ASTM Manual on Quality Control of Materials,copyright American Society for Testing Materials.Reprinted with permission.

Source: 1950 ASTM Manual on Quality Control of Materials,copyright American Society for Testing Materials.Reprinted with permission.

-A milling operation has historically produced an average thickness of 0.005 inch with an average range of 0.0015 inch.Currently,the first three items from each batch of 20 are inspected.Use Table 5.1.What is the value of the lower control limit for the x-bar chart?

Definitions:

Total Variable Cost

The sum of all costs that vary directly with the level of production or output.

Fixed Cost Per Unit

The total fixed costs of production divided by the number of units produced, decreasing as production volume increases.

Relevant Range

The level of activity within which the assumptions about fixed and variable costs in cost-volume-profit analysis remain valid.

Contribution Margin Ratio

A financial metric that shows the percentage of sales revenue that exceeds variable costs, indicating the portion contributing to covering fixed costs and generating profit.

Q11: One common point for inspection is at

Q70: A company's production facility,consisting of two identical

Q71: When the process choice is a job

Q91: The calling population in a queuing problem

Q95: A swim lane flowchart has a separate

Q124: Explain why a bottleneck limits system output.

Q125: Use the information in Figure 3.1.What is

Q144: Because a telephone customer service center has

Q159: The _ section of the Baldrige Performance

Q192: A sampling plan is best for evaluating