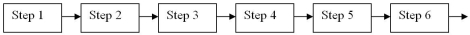

Consider the following production process.It is trying to meet a market demand of 250 units per week.  Step 1: Material release schedule

Step 1: Material release schedule

Step 2: Drilling (capacity is 300 units/week)

Step 3: Tapping (capacity is 150 units/week)

Step 4: Grinding (capacity is 300 units/week)

Step 5: Coating (capacity is 200 units/week)

Step 6: Inspection (capacity is 500 units/week)

a.Where should buffers be placed?

b.Which resource is the drum?

c.Where should the rope be placed?

d.Which resource is the bottleneck?

e.Which resource is the CCR?

Definitions:

Land Improvements

Enhancements to land that increase its value or usefulness, such as landscaping, fencing, and paving, which are usually depreciable over time.

Buildings

Physical structures owned by a business or organization, considered as fixed assets on a balance sheet.

Land

Land refers to a parcel of earth's surface, considered as property, and it's a fundamental resource for various types of real estate and agricultural activities.

Machinery and Equipment

Physical assets used in the production process to manufacture goods or provide services.

Q7: The break-even graph shown below represents the

Q23: The value stream mapping tool often requires

Q26: Use the information in Figure 5.2.What is

Q64: Which one of the following statements about

Q77: Using customer demand to activate production of

Q82: The Union Manufacturing Company is producing two

Q84: Customers demand muffalettas at the rate of

Q109: _ is a time-series method used to

Q182: Use Scenario 2.4 to solve this problem.What

Q199: The first unit of production takes 20