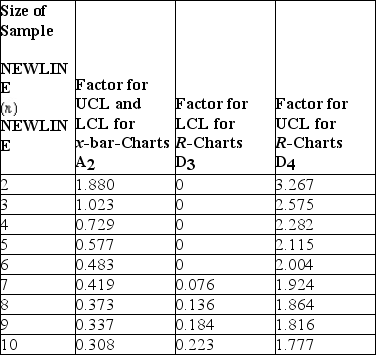

Table 5.11

Factors for Calculating Three-Sigma Limits for the  Chart and R-Chart

Chart and R-Chart

Source: 1950 ASTM Manual on Quality Control of Materials,copyright American Society for Testing Materials.Reprinted with permission.

Source: 1950 ASTM Manual on Quality Control of Materials,copyright American Society for Testing Materials.Reprinted with permission.

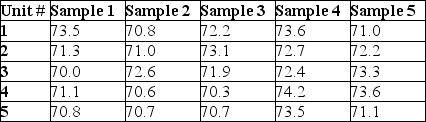

-Thermostats are subjected to rigorous testing before they are shipped to air conditioning technicians around the world.Results from the last five samples are shown in the table.Calculate control limits for a chart that will monitor process consistency.The correct control limits as (LCL,UCL) are:

Definitions:

Pessimistic

A tendency to anticipate unfavorable outcomes or emphasize the negative aspects of a situation.

Expected Time

An estimation of the duration it would likely take to complete a task, often used in project management for scheduling.

PERT Times

entails the estimated durations in the Program Evaluation and Review Technique, a method used in project management.

Optimistic Time

The shortest possible time in which a task or project can be completed, assuming everything goes better than expected.

Q4: An assembly line has to perform 10

Q71: Toyota sets up all of its operations

Q85: What are the four underlying principles of

Q86: The four bolts that hold the passenger

Q91: A firm gains competitive advantage by outperforming

Q124: Individuals high in agreeableness would likely seek

Q124: The process batch at the constraint in

Q137: If performance pressures increase too much,individuals begin

Q157: Taguchi's quality loss function should be centered

Q165: More often than not,process improvement takes place