SCENARIO 19-4

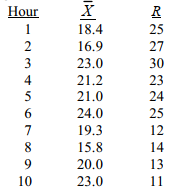

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds) is too erratic and adversely affects expected profits.The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours.The sample mean and range for each hour are listed below. She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds,respectively.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds,respectively.

-Referring to Scenario 19-4,suppose the supervisor constructs an x̄ chart to see if the process is in-control.What are the lower and upper control limits of this chart?

Definitions:

CCA Tax Shield

A reduction in taxable income in Canada, achieved by deducting the Capital Cost Allowance on assets.

Operating Cash Flow (OCF)

Cash generated from a firm's normal business operations.

Erosion Effects

Erosion effects describe the gradual decrease or undermining of value, benefits, or productivity, often due to external factors such as competition or technological advancements.

Q8: Referring to Scenario 17-7,at the two cluster

Q30: Referring to Scenario 9-11,if you select a

Q39: The Laspeyres price index uses the initial

Q44: Referring to Scenario 17-1,the sparklines enable you

Q62: Vertical analysis is a technique for evaluating

Q78: In measuring the effect size of the

Q86: Quick Changeover Techniques establish ways to eliminate

Q91: Referring to Scenario 17-4,the highest mean weekend

Q172: Referring to Scenario 18-8,the null hypothesis should

Q229: An agronomist wants to compare the crop