SCENARIO 19-4

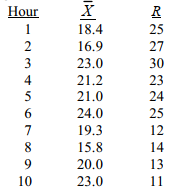

A factory supervisor is concerned that the time it takes workers to complete an important production task (measured in seconds)is too erratic and adversely affects expected profits.The supervisor proceeds by randomly sampling 5 individuals per hour for a period of 10 hours.The sample mean and range for each hour are listed below. She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds,respectively.

She also decides that lower and upper specification limit for the critical-to-quality variable should be 10 and 30 seconds,respectively.

-Referring to Scenario 19-4,what is the value of d2 factor?

Definitions:

Rework Labor

The effort and cost associated with correcting defective goods or services after they have been produced.

External Failure Cost

Costs incurred when a product or service fails to meet quality standards after being delivered to the customer, including returns, repairs, and warranty claims.

Quality Cost Report

A document that details the costs associated with preventing, detecting, and correcting defective work in a company.

Warranty Period

The specific time frame during which a manufacturer or seller commits to repair or replace defective products.

Q13: Referring to Scenario 20-6,what is the return-to-risk

Q17: Which of the following finds relationships in

Q37: Some consider bullet graphs little more than

Q37: The Paasche price index reflects more accurately

Q51: You have 5 stocks in your investment

Q63: Referring to Scenario 17-3,the highest probability of

Q96: Blossom's Flowers purchases roses for sale for

Q107: Referring to Scenario 19-2,which expression best characterizes

Q137: Referring to Scenario 16-13,what is your forecast

Q228: Referring to Scenario 12-20,there is sufficient evidence