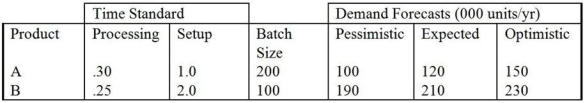

Larry's Wickets, Inc. is producing two types of products: A and B. Both are produced at the same machining operation. Because of demand uncertainties, the operations manager obtained three demand forecasts (pessimistic, expected, and optimistic). The demand forecasts, batch sizes (units/batch), processing times (hr/unit), and setup times (hr/batch) follow.

The machines operate on two 8-hour shifts, 5 days per week, and 50 weeks per year. The manager wants to maintain a 20 percent capacity cushion.

a. What is the minimum number of hours required of the machining equipment for the next year?

b. How many hours of capacity can the company expect from each machine?

c. What is the minimum number of machines needed (assuming no reliance on short-term options)?

d. What is the maximum number of machines needed (assuming no reliance on short-term options)?

Definitions:

Q8: Innovative Inc. is experiencing a boom for

Q17: The phase of project management that takes

Q31: A quality-focused CEO who promotes a culture

Q33: George P. Burdell owns a hot tub

Q90: It takes a service rep an average

Q105: An expansionist capacity strategy involves large, infrequent

Q114: Which of the following is a process

Q116: Using Table 7.14, what is the probability

Q133: A good risk management plan will contain

Q181: A professor's graduate assistant can grade a