Parts manufactured by an injection molding process are subjected to a compressive strength test.We monitor the compressive strength of the parts manufactured by this process using an  and an s control chart.Samples of size 9 are taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The overall mean of the sample means is

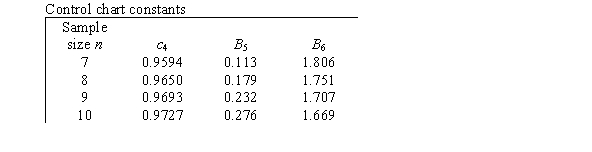

and an s control chart.Samples of size 9 are taken at regular intervals,and their mean compressive strength (in psi = pounds per square inch) and standard deviation are plotted on the charts in time order.The overall mean of the sample means is  = 81.2 psi,and the sample standard deviation of all measurements is s = 3.0 psi.Specifications call for the compressive strength of parts to be 80 ± 2.5 psi.The control chart constants are (partially) reproduced below.

= 81.2 psi,and the sample standard deviation of all measurements is s = 3.0 psi.Specifications call for the compressive strength of parts to be 80 ± 2.5 psi.The control chart constants are (partially) reproduced below.  What is the value of an estimate of the capability index Cp?

What is the value of an estimate of the capability index Cp?

Definitions:

Straight Line

In mathematics and statistics, a linear relationship or function that can be graphically represented as a straight line in Cartesian coordinates.

Correlation Coefficient

A statistical measure ranging from -1 to 1 that indicates the strength and direction of the linear relationship between two variables.

Scatterplot

A graphical representation of individual data points plotted on a two-dimensional plane, often used to observe and analyze the relationship between two variables.

Least Squares Regression Line

A straight line that best fits the data on a scatter plot, minimizing the sum of the squares of the vertical distances of the points from the line.

Q3: The square footage of the several thousand

Q11: The second letter of a word in

Q18: "Cramming" is a technique often used by

Q26: Suppose we are given the following information:

Q35: Researchers at a car resale company are

Q38: What is the major difference between a

Q45: The margin of error in a confidence

Q52: Multiple regression can be used for which

Q84: The moisture in a wet mix of

Q86: In a probability model,all possible outcomes together