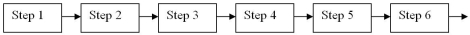

Consider the process shown that is trying to produce to meet a market demand of 250 units per week.  Step 1: Material release schedule

Step 1: Material release schedule

Step 2: Drilling (capacity is 300 units/week)Step 3: Tapping (capacity is 150 units/week)Step 4: Grinding (capacity is 300 units/week)Step 5: Coating (capacity is 200 units/week)Step 6: Inspection (capacity is 500 units/week)a.Where should buffers be placed?

b.Which resource is the drum?

c.Where should the rope be placed?

d.Which resource is the bottleneck?

e.Which resource is the CCR?

Definitions:

Aging of Accounts

A method used to categorize accounts receivable based on the length of time an invoice has been outstanding, often to identify potential collection issues.

Gross Price Method

An accounting method where inventory purchases are recorded at their gross price, without deducting any available cash discounts.

Net Realizable Value

The estimated selling price of goods, less the costs of their sale or disposal.

Bad Debt Expense

The cost associated with accounts receivable that a company does not expect to collect because customers default on payments.

Q3: Use the information in Figure 7.1.If each

Q21: A bank lobby with six teller windows,each

Q55: Use the information in Scenario 9.9.The firm

Q58: The final assembly schedule in a lean

Q67: A five S program includes the activities

Q68: Use the information in Table 7.9.How many

Q89: In a drum-buffer-rope system,the lot size that

Q120: The degree to which equipment,space,or labor is

Q121: A super computer-accessory discount store often has

Q172: The three sigma limits for a process