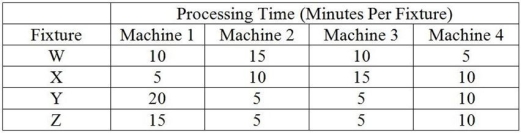

Table 5.3

King Supply makes four different types of plumbing fixtures: W, X, Y and Z. The contribution margins for these products are: $70 for Product W, $60 for Product X, $90 for Product Y and $100 for Product Z. Fixed overhead is estimated at $5,500 per week. The manufacture of each fixture requires four machines, Machines #1, 2, 3 and 4. Each of the machines is available for 40 hours a week and there is no setup time required when shifting from the production of one product to any other. The processing requirements to make one unit of each product are shown in the table. Weekly product demand for the next planning period has been forecasted as follows: 70 Ws, 60 Xs, 50 Ys and 30 Zs.

In the questions that follow, the traditional method refers to maximizing the contribution margin per unit for each product, and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

-Use the information in Table 5.3. Using the traditional method, in what sequence should the fixtures be scheduled for production?

Definitions:

Impossibility

A concept in contract law where unanticipated events make the fulfillment of a contract's terms unfeasible or unable to be completed.

Substitute

An alternative or replacement for something else, particularly in the context of products, goods, or services.

Statute of Limitations

A law that sets the maximum time after an event within which legal proceedings may be initiated.

Parol Evidence Rule

A legal principle that prevents the use of oral statements or extrinsic evidence to contradict or add to the terms of a written contract.

Q16: Long-term capacity plans deal with:<br>A)investments in new

Q21: A good risk management plan will contain

Q50: A wait-and-see capacity strategy minimizes the chances

Q50: A prime example of an internal failure

Q74: When considering the plan-do-study-act cycle for problem

Q89: With flexible automation,the ability to reprogram instructions

Q110: Champion Cooling Company uses a kanban system

Q124: Which one of the following is considered

Q152: Service providers with a line process tend

Q232: Describe the differences among make-to-order,assemble-to-order,and make-to-stock strategies