Use the scenario below to answer the following question(s) .

A company makes standard 115-inch-wide rolls of thin sheet metal,and slits them into smaller rolls to meet customer orders for widths of 13,16,and 25 inches.The demands for these widths vary from week to week.From a 115-inch roll,there are many different ways to slit 13-,16-,and 25-inch pieces.

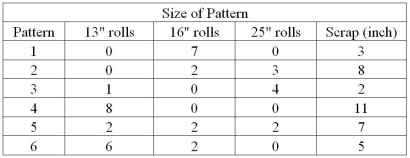

A cutting pattern is a configuration of the number of smaller rolls of each type that are cut from the raw stock.Of course,one would want to use as much of the roll as possible to avoid costly scrap.For example,one could cut seven 16-inch rolls,leaving a 3-inch piece of scrap.Finding good cutting patterns for a large set of end products is in itself a challenging problem.Suppose that the company has proposed the following cutting patterns:  Demands this week are 1,000 13-inch rolls,1,430 16-inch rolls,and 1,260 25-inch rolls.The problem is to develop a model that will determine how many 115-inch rolls to cut into each of the six patterns in order to meet demand and scrap.

Demands this week are 1,000 13-inch rolls,1,430 16-inch rolls,and 1,260 25-inch rolls.The problem is to develop a model that will determine how many 115-inch rolls to cut into each of the six patterns in order to meet demand and scrap.

Define Xi to be the number of 115-inch rolls to cut using cutting pattern i,for i = 1,…,6.

Note that Xi needs to be a whole number because each roll that is cut generates a different number of end items.

-Identify the constraint specified for 13-inch rolls.

Definitions:

After-Tax Net Income

The amount of profit remaining after all taxes have been deducted from total revenue.

Q19: Which of the following is a decision

Q20: The number of television sets shipped from

Q34: The constraint for 16-inch rolls is formulated

Q38: Balance constraints essentially state that "input <

Q38: Which of the following is the basic

Q54: Describe the procedure used to define assumptions

Q77: Any optimization model is completely deterministic,that is,no

Q81: Which of the following is the inequality/equality

Q107: Who defined power as the ability of

Q141: The text cites the federal government's reserve