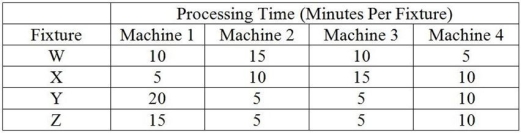

Table 5.3

King Supply makes four different types of plumbing fixtures: W, X, Y and Z. The contribution margins for these products are: $70 for Product W, $60 for Product X, $90 for Product Y and $100 for Product Z. Fixed overhead is estimated at $5,500 per week. The manufacture of each fixture requires four machines, Machines #1, 2, 3 and 4. Each of the machines is available for 40 hours a week and there is no setup time required when shifting from the production of one product to any other. The processing requirements to make one unit of each product are shown in the table. Weekly product demand for the next planning period has been forecasted as follows: 70 Ws, 60 Xs, 50 Ys and 30 Zs.

In the questions that follow, the traditional method refers to maximizing the contribution margin per unit for each product, and the bottleneck method refers to maximizing the contribution margin per minute at the bottleneck for each product.

-Use the information in Table 5.3. Using the bottleneck method, what is the optimal product mix?

Definitions:

Brand Name

A distinctive name identifying a product, service, or company, often acting as a signifier of quality and reliability.

Economic Profit

The profit a firm or individual makes after deducting both explicit and implicit costs.

Imperfect Substitutes

Goods or services that can replace each other to some extent, but have differences in features, quality, or price that make them not completely interchangeable.

Brand Names

Names given to products or services by companies to distinguish them from competitors.

Q37: What is a Drum-Buffer-Rope system for planning

Q57: The Japanese term for continuous improvement in

Q69: Consider the following data concerning the performance

Q72: Capacity is the maximum rate of output

Q79: Use the information in Table 5.3.Using the

Q80: Using Table 7.9,what is the difference,in dollars,between

Q80: If demand is increasing,and you also prefer

Q95: Consider consecutive processes A-B-C,where process A has

Q105: _ is the documentation and detailed understanding

Q145: Construct a 3-sigma x-bar chart for the